PENGARUH TEMPERATUR DAN WAKTU HOMOGENISASI TERHADAP KARAKTERISTIK PELAT PADUAN AG3NE

DOI:

https://doi.org/10.17146/urania.2018.24.2.4391Keywords:

AG3NE, AlMgSi, Homogenization, Characterization, Structural materialAbstract

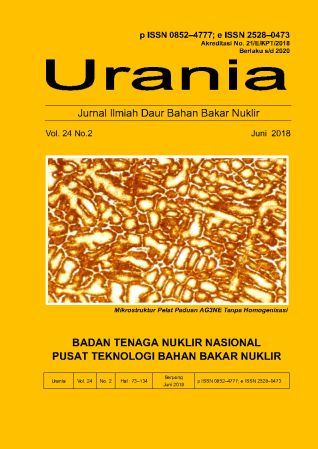

Investigation on the effects of homogenization temperature and time on AG3NE alloy plate has been done. AG3NE alloy is used as cladding material of research reactor fuel. Ingot of AlMgFeSi melt was sampled for several tests and examination such as chemical composition, hardness, microstructure, phase, density and corrosion. Composition analysis shows that the alloy is composed of Al= 96.110%, Fe= 0.188%, Mg= 2.333% and Si= 0.355%.The hardness value for AG3NE is 153.33 HV for samples treated with rapid cooling and 72.70 HV for samples treated with slow cooling. Microstructure examination with optical microscope shows that AG3NE alloy without homogenization consists of flat grains with a fraction of dendrite of 0.02 mm mean diameter, while samples homogenized at 500°C at varied temperatures of 1, 2, 3, and 4 hours consist of grains with 0.01 mm, 0.02 mm, 0.03 mm and 0.04 mm respectively. Phase analysis with X-Ray Diffractometer indicates the existence of Al (ά) and FeSiAl5 phases at 2θ of 38.24° - hkl (119) and 44.446° - hkl (209) with 100% and 76.6% intensity respectively. The measured density of AG3NE, however, is similar to that of AlMgSi as material for comparison, the values of which are 2.6893 ± 0.0013 g/cm3 for AG3NE and 2.6910 ± 0.0283 g/cm3 for AlMgSi. Corrosion rate analysis shows that the corrosion rate for AG3NE is lower than that for AlMgSi. Based on the characterization for chemical composition, microhardness, microstructure, density and corrosion rate, it is concluded that AG3NE alloy can be used as a candidate for cladding material for research reactor fuel.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2018 Author(s)

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.