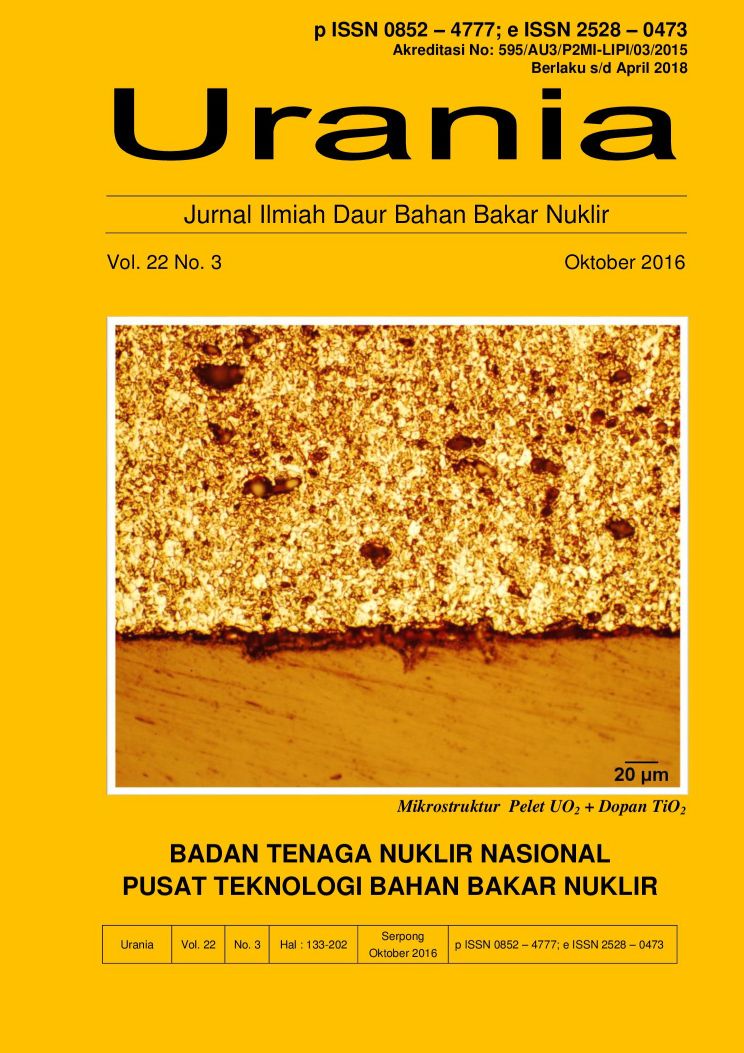

KARAKTERISASI LAPISAN PENYERAP DAPAT BAKAR PADA PERMUKAAN PELET UO2 + DOPAN TiO2

DOI:

https://doi.org/10.17146/urania.2016.22.3.3182Keywords:

Surface layer, Burnable absorber, UO2 pellet, Microstructures, Microhardness, Chemical composition, Crystal structureAbstract

Burnable absorber layer on the surface of UO2 + doped TiO2 pellets have successfully created using RF sputtering methods. The objective of this research is to obtain of microstructure characters of UO2 + doped TiO2 pellets, thickness, micro hardness, chemical composition and crystal structure of burnable absorber layer on the surface of UO2 pellets. The methods used are the microstructure and layer thickness using optical microscopy, layer hardness with micro Vickers hardness method, chemical composition by XRF spectrometry, and crystal structure by X-ray diffraction. The results showed that the larger of TiO2 content in the pellets then the greater of the grain size in the microstructure of the pellets and the thicker of the layer formed on the surface of UO2 pellets. The hardness of surface layer of UO2 + doped TiO2 sintered pellets are equal and does not depend on the dopant concentration of TiO2. The surface layer of UO2 + 0.3 % TiO2, UO2 + 0.5 % TiO2 and UO2 + 0.7 % TiO2 sintered pellets are containing zirconium respectively 1.97 mg, 2.47 mg and 4.81 mg. Burnable absorber layer on the surface of UO2 + doped TiO2 sintered pellets have ZrB2 phase with a hexagonal crystal structure.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2017 Author(s)

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.