Powder Coating Waste Utilization as a Filler in High-Density Polyethylene (HDPE) Coupled with PP-g-MA

DOI:

https://doi.org/10.55981/jsmi.2025.4963Keywords:

Composite, Coupling Agent, Polyester, Powder CoatingAbstract

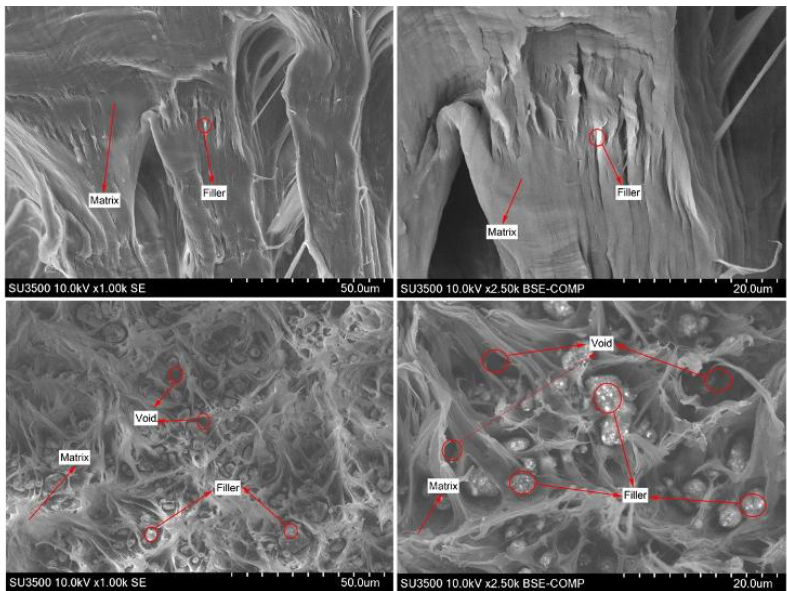

The powder coating process in industry typically generates waste during curing process. This non-recyclable and hazardous powder-coating waste is utilized as filler material in this research. Polyester was employed as filler in the High-Density Polyethylene (HDPE) Matrix Composite. The study investigated the impact of polyester composition at 20%, 30%, and 40%, with 5% of PP-g-MA coupling agent addition. To assess the effect as a coupling agent, 0%, 2%, 5%, and 10% of PP-g-MA were added to the composite with a matrix-filler ratio of 70:30. Mixing was conducted using the hot melt mixing method at 180°C and mixing speed 60 rpm, with duration 9 minutes. The characterization and tests include the measurements of surface tension using SEM, FTIR, TGA, DSC, and micro-tensile tests. The results indicate that polyester and PP-g-MA composition decrease the thermal properties of the composite. However, increasing the filler addition by up to 30% and PP-g-MA addition by up to 5% enhances the thermal properties. The tensile strength and stiffness of the composite with polyester filler and PP-g-MA are higher than pure HDPE. These are achieved with the addition of polyester filler 20% and a coupling agent composition of PP-g-MA at 5%.

Downloads

References

[1] A. Chamas, H. Moon, J. Zheng, Y. Qiu, T. Tabassum, J. H. Jang, M. Abu-Omar, S. L. Scott, and S. Suh. "Degradation Rates of Plastics in the Environment." ACS Sustain Chem Eng, vol. 8, no. 9, pp. 3494-3511, 2020.

https://doi.org/10.1021/acssuschemeng.9b06635

[2] Y. Kismet and M. H. Wagner. "Mechanical, thermal, and morphological properties of powder coating waste reinforced acetal copolymer." Polym. Test, vol. 82, no. February 2020, p. 106322, 2020.

https://doi.org/10.1016/j.polymertesting.2019.106322

[3] Y. Kismet, A. Dogan, and M. H. Wagner. "Thermoset powder coating wastes as filler in LDPE - Characterization of mechanical, thermal and morphological properties." Polym. Test, vol. 93, no. January 2021, p. 106897, 2021.

https://doi.org/10.1016/j.polymertesting.2020.106897

[4] Z. Du, S. Wen, J. Wang, C. Yin, D. Yu, and J. Luo. "The Review of Powder Coatings." Journal of Materials Science and Chemical Engineering, vol. 4, no. 3, pp. 54-59, 2016.

https://doi.org/10.4236/msce.2016.43007

[5] J. Fu, M. Krantz, H. Zhang, J. Zhu, H. Kuo, Y. M. Wang, and K. Lis. "Investigation of the recyclability of powder coatings," Powder Technol., vol. 211, no. 1, pp. 38-45, 2011.

https://doi.org/10.1016/j.powtec.2011.03.016

[6] Y. Kismet and M. H. Wagner. "Enhancing the potential of employing thermosetting powder recyclates as filler in LLDPE by structural modifications." Journal of Polymer Engineering, vol. 37, no. 3, pp. 287-296, 2017.

https://doi.org/10.1515/polyeng-2015-0498

[7] A. C. Abhyankar, N. R. Edmonds, and A. J. Easteal. "Use of waste powder coatings as binders for the manufacture of composite materials." WIT Transactions on Ecology and the Environment, vol. 106, pp. 493-502, 2007.

https://doi.org/10.2495/ECO070461

[8] S. Giat S., Sudirman, D. I. Anwar, F. Lukitowati, and B. Abbas. "Sifat Fisis Dan Mekanis Komposit High Density Polyethylene (HDPE) - Hydroxyapatite (HAp) Dengan Teknik Iradiasi Gamma." Jurnal Kimia dan Kemasan, vol. 37, no. 1, pp. 53-60, 2015.

https://doi.org/10.24817/jkk.v37i1.1812

[9] M. O. Awan, A. Shakoor, M. S. Rehan, and Y. Q. Gill. "Development of HDPE composites with improved mechanical properties using calcium carbonate and NanoClay," Physica B Condens Matter, vol. 606, p. 412568, 2021.

https://doi.org/10.1016/j.physb.2020.412568

[10] N. C. Bleach, S. N. Nazhat, K. E. Tanner, M. Kellomäki, and P. Törmälä. "Effect of filler content on mechanical and dynamic mechanical properties of particulate biphasic calcium phosphate - Polylactide composites." Biomaterials, vol. 23, no. 7, pp. 1579-1585, 2002.

https://doi.org/10.1016/S0142-9612(01)00283-6

[11] H. M. Ng, N. M. Saidi, F. S. Omar, K. Ramesh, S. Ramesh, and S. Bashir. "Thermogravimetric Analysis of Polymers." Encyclopedia of Polymer Science and Technology, pp. 1-29, 2018.

https://doi.org/10.1002/0471440264.pst667

[12] A. H. Awad, A. Aly Abd El-Wahab, R. El-Gamsy, and M. H. Abdel-latif. "A study of some thermal and mechanical properties of HDPE blend with marble and granite dust." Ain Shams Engineering Journal, vol. 10, no. 2, pp. 353-358, 2019.

https://doi.org/10.1016/j.asej.2018.08.005

[13] J. Aburto, S. Thiebaud, I. Alric, E. Borredon, D. Bikiaris, J. Prinos, and C. Panayiotou. "Properties of octanoated starch and its blends with polyethylene." Carbohydr. Polym., vol. 34, no. 1-2, pp. 101-112, 1997.

https://doi.org/10.1016/S0144-8617(97)00053-2

[14] Waryat, M. Romli, A. Suryani, I. Yuliasih, and S. Johan. "The Characterization of Morphology, Thermal, Physic-Mechanic, and Barrier of Biodegradable Plastic from Thermoplastic Starch-LLDPE/HDPE Blends." Agritech, vol. 33, no. 2, pp. 197-207, 2013.

https://doi.org/10.22146/agritech.9800

[15] M. Poletto. "Effects of the coupling agent structure on the adhesion of recycled polystyrene wood flour composites: Thermal degradation kinetics and thermodynamics parameters." J. Compos. Mater., vol. 50, no. 23, pp. 3291-3299, 2016.

https://doi.org/10.1177/0021998315618250

[16] W. D. Callister and D. G. Rethwish. Materials Science and Engineering An Introduction. 2018.

[17] Karolina Glogowska and Luksz Majewski. "The effect of selected natural fillers on the mechanical properties of low-density polyethylene." Technical Transaction Mechanics, vol. 114, no. 10, pp. 155-166, 2017.

[18] M. Yang, J. Su, Y. Zheng, C. Fang, W. Lei, and L. Li, "Effect of Different Silane Coupling Agents on Properties of Waste Corrugated Paper Fiber/Polylactic Acid Composites," Polymers (Basel), vol. 15, no. 17.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Shinta Dewi Ariantika, Mochamad Chalid, Azizah Intan Pangesty

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.